Depending on your need and budget, we can offer a wide range of exclusive solutions for welding inspection with very high added value. This will allow you to visualize and monitor in real time the welding processes and the automation of the quality control.

1) CMOS HDR (High Dynamic Range) cameras: NIT

The NIT-Magic implements a patented HDR technolog for logaritmic response of the sensor. In this way 140fB dynamic range can be achieved

This avoids the saturation of the image and allows watching in the same scene the very hot and bright areas and the very dark ones, for instance how the fusion zone solidifies with great detail.

2) 900-1700nm SWIR cameras, InGaAs HDR (High Dynamic Range): NIT

The NIT-WiDy-SWIR uses the same technology but with InGaAs sensors, to reach 120dB dynamic. They don't need TEC thus the consumption and weight are very low.

The NIT-WiDy-SenS has the advantages of the WiDy-SWIR and adds a linear operation mode allows high sensitivity (HS) imaging. They have built-in TEC that is activated in the lienar mode (HS) and deactivated in the logaritmic mode (HDR).

With these cameras you will have an unbeatable dynamic range and similarly to the VIS cameras NIT-Magic you will see the SIWR image of the welding without saturation.

3) Polarized camera: Sony

Sony manufactures an image sensor with 4 polarization filters for each image pixel. Each pixel has one of the 4 polarizing filters and 4 pixels give complete information on the state and degree of polarization. Sony also builds the sensor on its own cameras. In general, the Sony SNY-XCG-CP510 polarized cameras are the best on the market (reliability, failure and EM discharge resistance, software,…).

Thanks to the sensor, the image is decomposed into the 4 images of the polarizations (this is a rough approximation) which allows detecting defects that a normal image does not see, seeing through fog or glass, ... or welding processes facilitating the inspection by removing flare.

Thanks to Sony's proprietary SNY-XPL-SDKW SDK software that implements a large variety of algorithms and corrections, the polarized camera is tremendously useful. Otherwise with only the raw data from the sensor you would need a lot of programming and a polarization expert. Some advantages of using the Sony SDK with proprietary algorithms are:

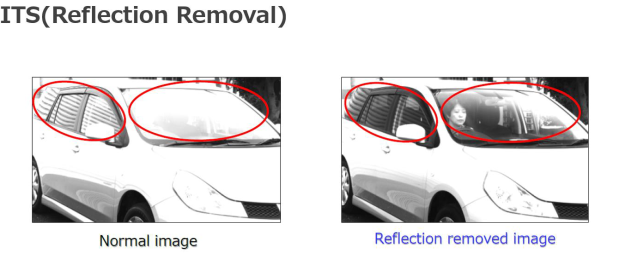

- reflections removal: this is very relevant for welding, where what you want to see is often masked by reflections from the joint

- reflections improvement: selection of the best angle to maximize the reflection at each pixel

- interpolation of all pixels to obtain an optical resolution of approximately 4MP. If only the sensor were used without this algorithm the resolution would be 1.3MP

These images are clear examples of what camera + SDK can achieve by removing reflections:

The key difference between the Sony polarized camera and the NIT high dynamic range camera is:

- polarized SNY-XCG-CP510: removes reflections and distortions

- HDR NIT-MAGIC: ultra large dynamic range 140dB to image simultaneously the welding spot and also the surroundings without saturation

4) Thermography cameras: InfraTec

Although they are not cameras intended for inspection or visualization of welding as such, if what you have to do is measure the temperature, then they are a good option. Those of InGaAs can also be, since the temperatures reached in the fusion zone are usually high enough for the InGaAs to be able to record them with the help of additional software (we do not provide it).

The problem is often that thermal imaging cameras are slow and reaching high measurement rates requires large or expensive cooled sensors, inherently expensive. But if the applications demands it and the manufacturing justifies the investment cooled thermal cameras are the best option for 2D dynamic temperature measurement. Here you can see the models and features:

- Image IR: cooled

- VarioCam HD(x): uncooled

In this video you can check the image quality of the Image IR cameras in welding inspection: